Vaso Care – Silicone Wear is one of the leading companies in the field of manufacturing technology for prosthetic limbs made of medical silicone, with the aim of providing effective solutions for people who have lost their limbs as a result of amputation or damage. The institution was established with a leadership and innovative vision under the supervision of Dr. Yazid Al-Daoudia, who has extensive experience in the field of medicine and technology.

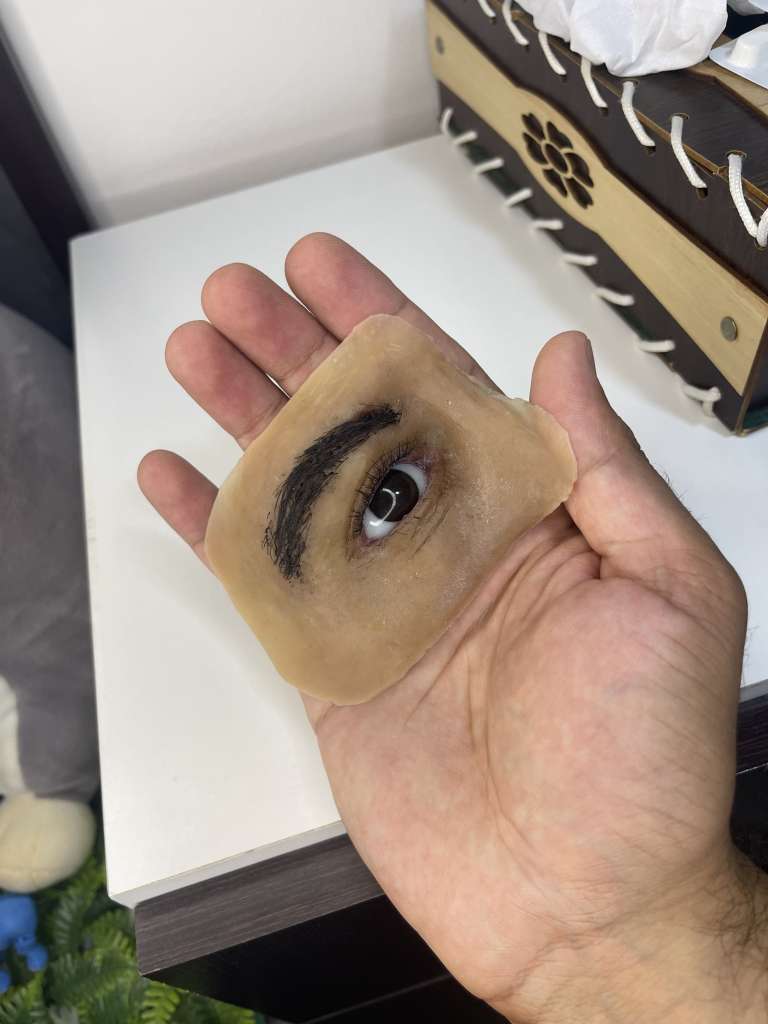

The technology of manufacturing prosthetics from medical silicone is a qualitative step in the field of prosthetics, as it provides patients who need stable and comfortable prostheses with movement and a natural appearance. Medical silicone is flexible, corrosion resistant and durable, making it an ideal material for making prosthetics.

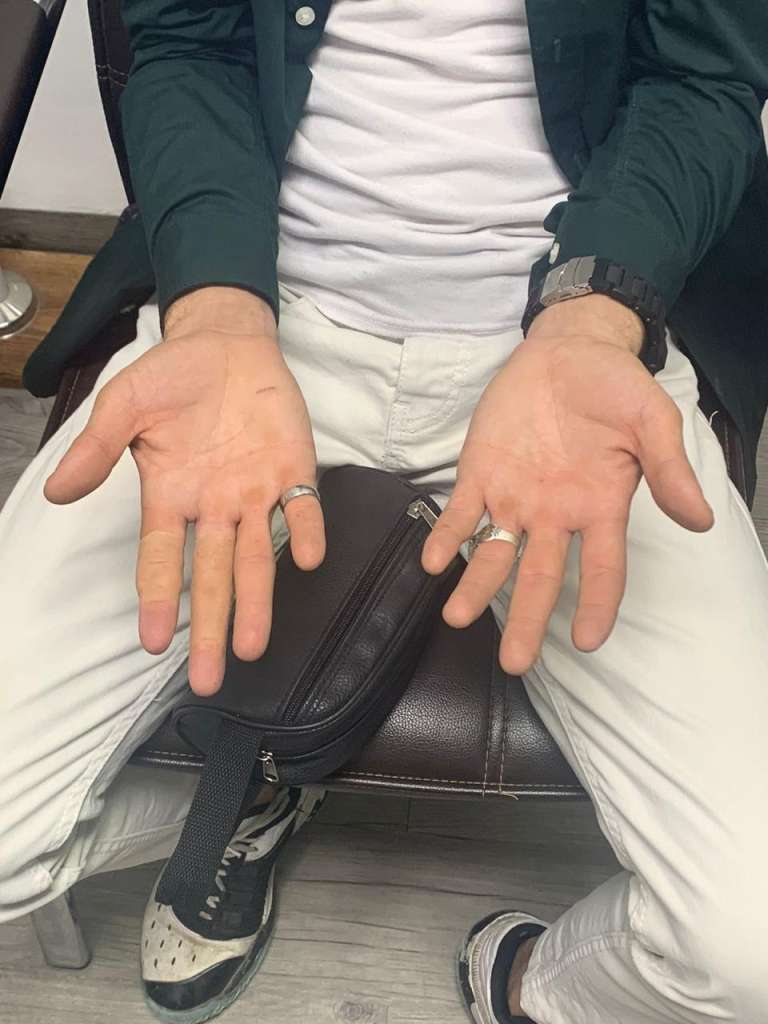

Vaso Care – Silicone Wear provides comprehensive services that include designing, manufacturing and customizing prosthetics based on the needs of each individual patient. The institution is distinguished by a team of experts specialized in designing and shaping prosthetic limbs using the latest technologies and materials, ensuring high quality and accuracy of work.

Vaso Care – Silicon Wear aims to improve the quality of life of patients suffering from limb loss, by providing advanced manufacturing technologies and customized solutions tailored to each individual’s needs. The Foundation also seeks continuous development and innovation in the field of prosthetic limb manufacturing technology, in order to provide the best solutions and services to patients and meet their aspirations.

3D printing technology is increasingly used in many fields, including the manufacture of prosthetics. 3D printing technology can be used to design and manufacture silicone limbs intended to replace amputated limbs.

The general steps for shaping and detailing silicone limbs using 3D printing technology to replace amputated limbs include:

- CAD (Computer-Aided Design) programs are used to design the 3D model of the amputated limbs based on precise measurements of the person concerned.

- The design must be precise to ensure a perfect fit for the individual and provide optimal comfort.

- After the model design is completed, it is converted into an STL (Stereolithography) file that is used in 3D printing processes.

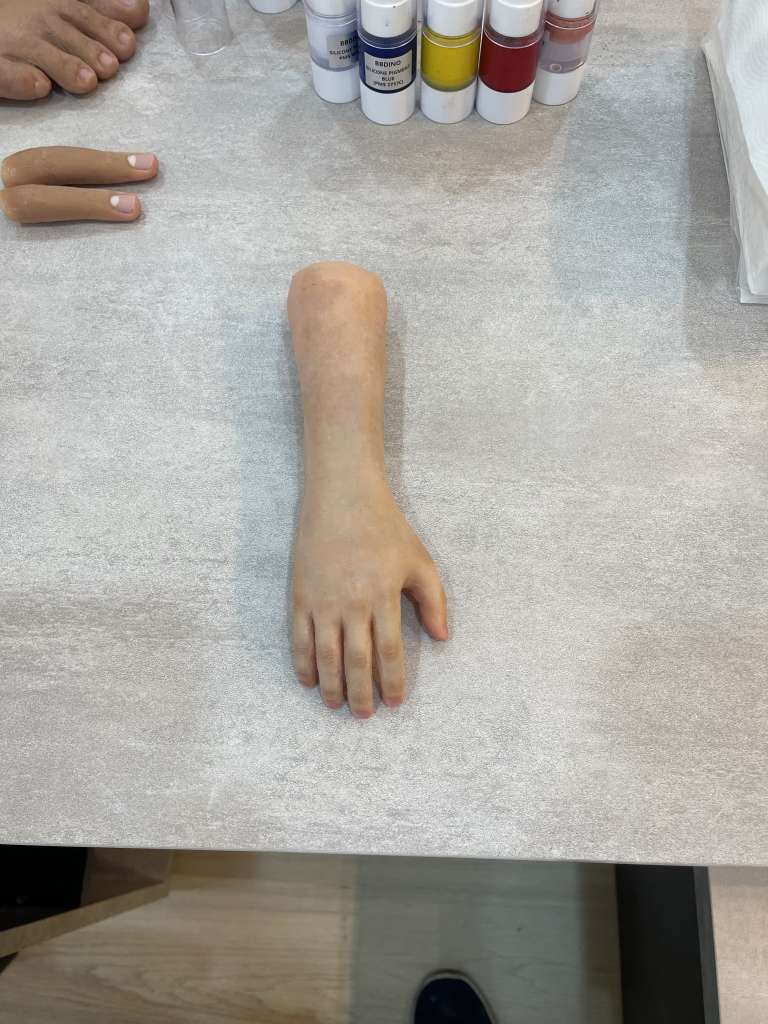

- A 3D printer is used to print the model with the appropriate materials, which can be flexible silicone materials.

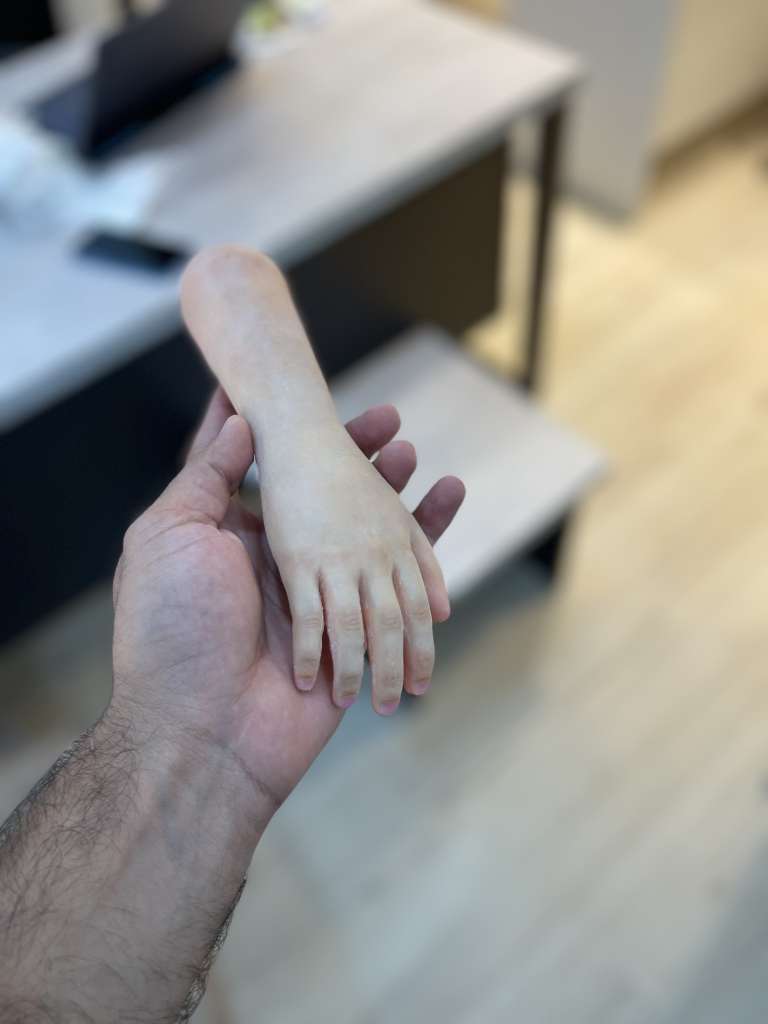

- Once the model is printed, it is shaped and detailed to achieve the final texture and shape of the amputated limb.

- Specialized tools such as knives and heat tools can be used to shape and modify the silicone according to the person’s needs.

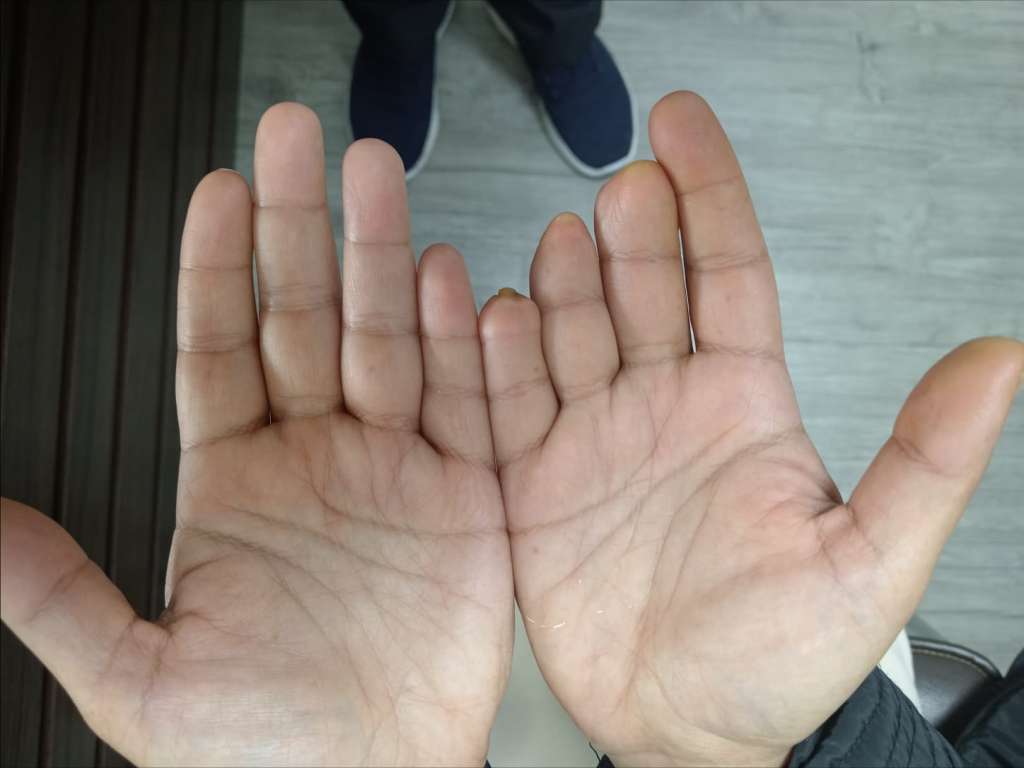

- After shaping and detailing, a final adjustment is made to ensure a perfect fit for the amputated limbs.

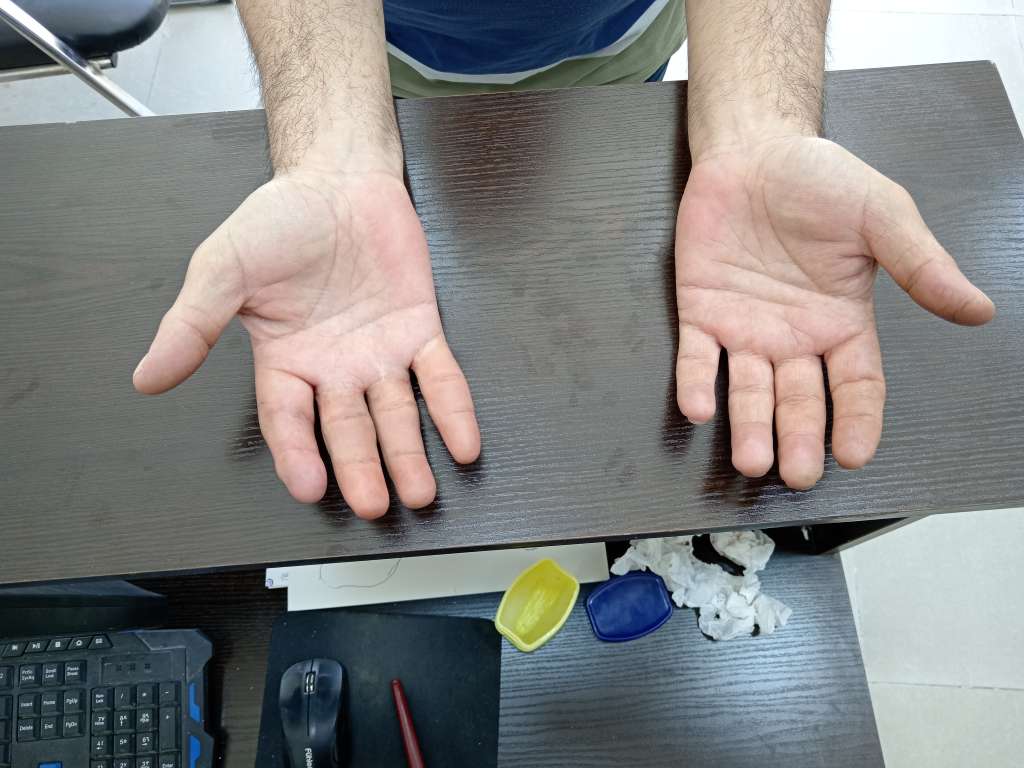

- The limbs manufactured are tested to ensure they provide the correct comfort and function and meet the person’s needs.

After adjusting and testing, final finishing operations are performed on the amputated limbs, including applying appropriate colors and patterns to match the individual’s skin and look as natural as possible.

- The necessary support is provided to the person using amputated limbs, including guidance on the use of prosthetic limbs and ensuring their comfort and safety.

- Continuous follow-up is provided to ensure the limbs are performing properly and the person’s needs are being met.

These steps aim to provide customized and effective silicone prostheses to replace amputated limbs, which contributes to improving the quality of life of the individuals involved.

Silicone Wear offers a group of innovative solutions to replace limbs with medical silicone, which is considered one of the best prosthetic alternatives in this field

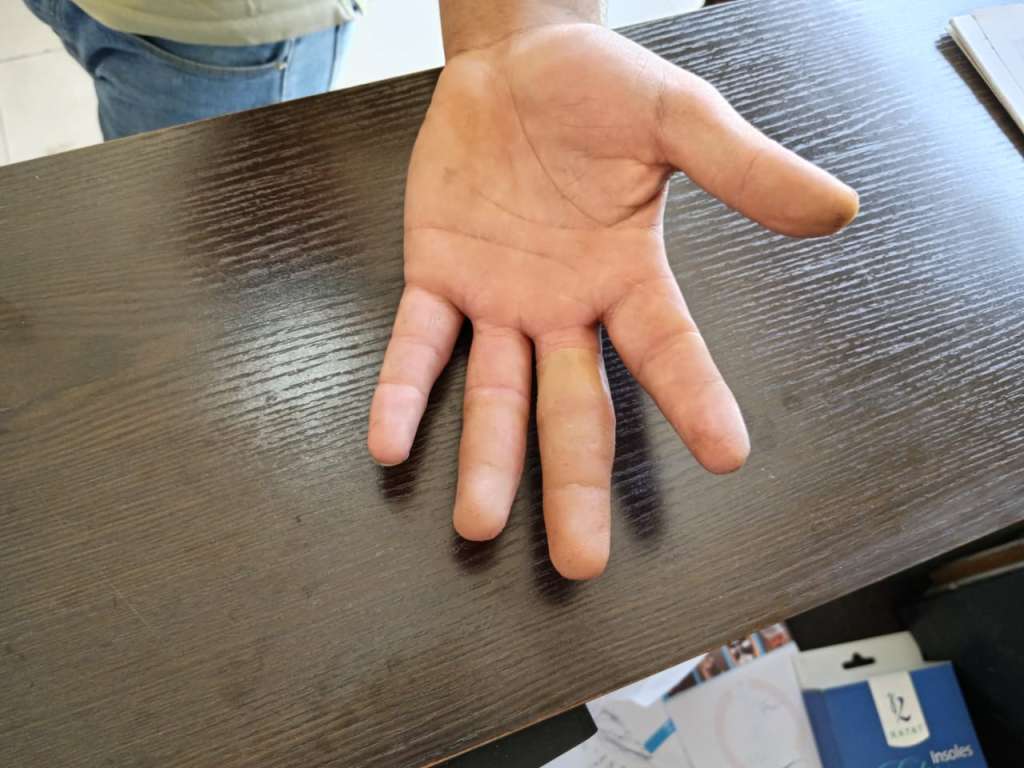

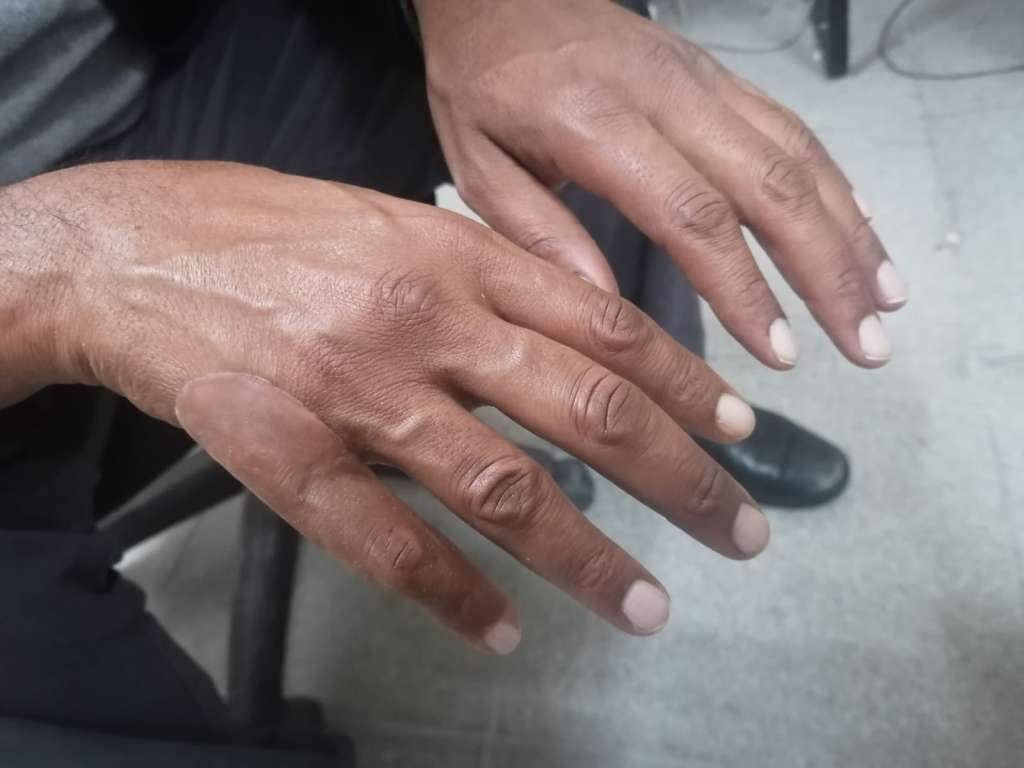

- Silicone Fingers

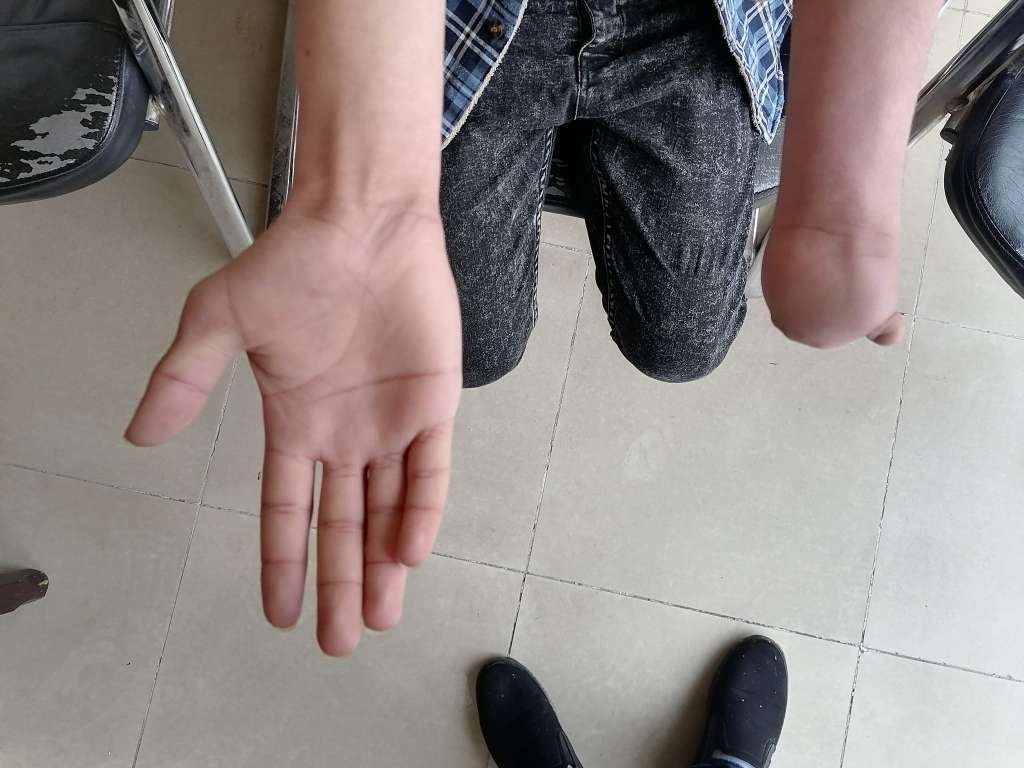

- Silicone Partial Hand

- Below Elbow Cosmetic Cover

- Silicone Toes Solutions

- Partial Foot Solutions

- Below Knee Cosmetic Cover

- Above Knee Cosmetic Cover

- Cosmetic Silicone Nose

- Cosmetic Silicone Ears